| 1.2379 | Х12МΦ |

It is most available and most popular of the cold work tool. 1.2379 is a High-carbon, high-chromium tool steels are subcategories of cold work tool. It is containing molybdenum and air hardening, and therefore has a high degree of dimensional stability in heat treatment. Although it can be quenched in oil, the movement is slightly greater when oil quenched. It has very high wear resistance, which increases with greater carbon and vanadium content. 1.2379 steel may be satisfactorily welded using the atomic hydrogen, oxy-acetylene, gas tungsten-arc, and shielded-metal-arc processes.

| %C | %Si | %Mn | %P | %S | Cr | Mo | V |

| 1,50-1,60 | 0,10-0,40 | 0,20-0,60 | 0,030 | 0,030 | 11,0-13,0 | 0,70-1.00 | 0,70-1.00 |

Hot working:

Forging temperature range: 1170-850℃

Note: Heat to 1170 ℃. Do not forge below 850.

Heat treatment:

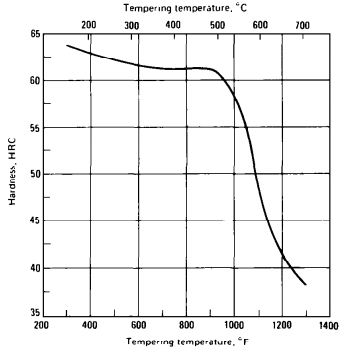

| soft annealing | Hardness HB30 | hardeninig | tempering | temper hardness(HRC) |

| 840-860 | 250 | 1020-1040 | 180-250 | 64 |

Main application:

Cutting dies sensitive to breakage, thread rolling dies, reamers, sockets

Shape of product:

Round, flat, step shape, ring, disc other shape depend on customer needs